Business

Peachtree Corner’s ControlRad is Making Radiation Safe for Medical Staff [Podcast]

Published

5 years agoon

More than ever before is the general public concerned for the health and safety for the brave

men and women in our medical and healthcare system. ControlRad and CEO Guillaume

Bailliard, our guest on today’s episode, have developed special medical technology to protect

both medical staff and patients from excess radiation. Join Rico Figliolini, Patrizia Winsper, and Guillaume as they discuss the inner workings of this amazing and life-saving technology.

Resources:

Website: https://www.controlrad.com

“The way our device works is… that we add an accessory to existing x-ray units that is a semi-transparent filter… that moves in real time… depending on what the physician needs to see on the screen. So we’re able to radically and dramatically reduce radiation, unnecessary radiation to both patients and medical staff using our device.”

Guillaume Bailliard

Timestamp:

[00:00:30] – Intro

[00:03:13] – ControlRad’s Device

[00:07:48] – Input Devices

[00:09:25] – Using Existing Technology

[00:10:23] – ControlRad’s Consumers

[00:12:19] – Consolidation

[00:13:42] – Other New Products

[00:14:27] – ALARA

[00:16:14] – Repercussions of Radiation

[00:18:57] – Case Studies

[00:20:42] – Time in Development

[00:22:02] – Moving to Peachtree Corners

[00:24:08] – Effects of COVID-19 on ControlRad

[00:28:29] – Closing

Podcast transcript

Rico: [00:00:30] Hi everyone. This is Rico Figliolini, host of the Peachtree Corners Life. Glad that you’re joining up, whether it’s live from on this feed with Facebook or you’re joining us on our podcast or YouTube video. I would appreciate it if you follow us online, currently if you like Facebook page for Peachtree Corners Life, you get notification of our live stream so that’d be great to do. Before we get to our today’s show, great guest to follow up to a cover story that we did an issue back about vibrant technology in the heart of Peachtree Corners. I just want to introduce our sponsor for the family of podcasts we do, which is Hargray Fiber. Hargray Fiber is a company that deals in fiber optic cable, communications, IT management, bundle services, throughout the Southeast. They’re in our communities. They’re doing great work in our communities too, especially now reaching out, providing free internet services per company, doubling bandwidths for existing customers. They’re doing a lot of things out there to make teleworking way easier. To find out more about them check them out HargrayFiber.com. We appreciate their sponsorship. So now let’s join with my cohost Patrizia Winsper, who wrote the article on these technology companies and today’s guest, she’s going to introduce him. I’m going to pick them on screen right now, Patrizia go ahead and introduce our guest today.

Patrizia: [00:01:51] Good afternoon, everyone. I have the sincere pleasure of introducing to you, CEO of ControlRad Guillaume Bailliard. Hi Guillaume.

Guillaume: [00:02:02] Hi everyone. Thanks for having me on.

Patrizia: [00:02:05] How are you doing today Guillaume?

Guillaume: [00:02:07] Doing fantastic. It’s a beautiful day outside.

Patrizia: [00:02:10] Awesome. It’s such a great time to do a podcast about some positive news and some great innovations that are taking place right here in Peachtree Corners. So I hope everyone has a chance to just settle down with us for a little bit and think happy thoughts and listen to some good news that’s going on. Right Rico?

Rico: [00:02:27] Yes, absolutely. Our guest is actually in the city of Peachtree Corners and he’s at his office at Tech Park. Right Guillaume?

Guillaume: [00:02:39] That’s right. I’m here in Peachtree Corners at the office on Scientific Drive, absolutely. So we are, today we’re doing some testing inside the, our laboratory here in the office. So we’re here to support and review the testing.

Rico: [00:02:55] For sure you’re doing this socially safe and all that, I imagine, right?

Guillaume: [00:02:59] I am. I did take off my 95 mask that I have with me here, but I took it off here for this interview.

Rico: [00:03:05] Excellent. Good. So let’s, let’s get right down to it then. Why don’t we ask, Patrizia did you want to show the magazine?

Patrizia: [00:03:13] Just wanted to point out that this is a story that appeared on the cover of our February, March, 2020 issue. And ControlRad is being featured today in this podcast, and of course that’s Guillaume Bailliard, CEO. Now if we’re looking at the name of your company, Guillaume, ControlRad, let’s think control radiation. This company has come up with a medical device that actually helps the medical professionals. Who are doing these procedures on a daily basis and protecting them or controlling that excess radiation that is unnecessary and that is currently inevitable without your device. So let’s talk about ControlRad’s medical device and exactly how is it that you are performing these procedures sparing both surgeons and patients, the exposure to that unnecessary scatter radiation.

Guillaume: [00:04:16] Okay, great. Yeah, so what people, you know, through this COVID-19 pandemic are now more appreciating than ever is that medical professionals put their lives at risk for treating patients. And our technology helps radically and dramatically reduce the life altering risks associated with radiation exposure to the medical staff. So as an example, when you’re getting, let’s say, a stent deployed in your heart to open up a blockage. A cardiologist will use a cath lab, which is a x-ray unit that continuously deploys x-ray to see inside your body to deploy that stent. The patient gets radiated one time, but the medical staff, the physician and the nurses and everybody else in the room will get radiated their entire lives as they do multiple of these procedures per day and throughout the year. A typical cardiologist will get exposed the equivalent of 150,000 chest X-rays throughout their lifetime. So it’s very similar to the NFL concussion story where we knew these risks were there for a long time. It took a couple of key cases for that, for this to surface as an issue, and we’ve deployed a technology to help reduce that risk. And the risks are dramatic. There is two times the risk of left brain tumors. There’s a 50% increase in incidents in cataracts. There’s a 34% increase in stroke incidents when compared to other physicians that are not in the x-ray room. So both patients and medical staff are, get dramatic, dramatically less radiation using our device. And that’s how, and basically the way our device works is, I think to answer your question Patrizia, is that we add an accessory to existing x-ray units that is a semi-transparent filter. Thank you for showing the image that moves in real time based on where the physician needs to, what, depending on where the physician needs to see on the screen. So we’re able to radically and dramatically reduce radiation, unnecessary radiation to both patients and medical staff using our device.

Patrizia: [00:06:34] So your filter is situated under the patients?

Guillaume: [00:06:38] That’s correct. The filter is under the patient right above the tube. The x-ray tube that hits the patient. I think you’ve got to move it over just a little, right there where the extra tube shoots through the patient we retrofit and add our filters to existing x-ray units. Which is a bonus for administrators because you don’t have to go out and buy a brand new x-ray unit or a brand new cath lab unit. We can retrofit your existing cath lab or your existing C-arm.

Patrizia: [00:07:10] So your device is retrofitted on the machine right here.

Guillaume: [00:07:13] That’s correct.

Patrizia: [00:07:14] And then let’s talk about this.

Guillaume: [00:07:18] And that is a tablet and the tablet, this is placed next to the patient where the physician is and the physician can select on the tablet and basically draw a region of interest to move the filter in the right location. So basically what you have is you have a tablet that is the input device, and then you have filters that are moved based on where the physician is looking on the patient.

Patrizia: [00:07:48] Now Guillaume, I realize you deal with this every day, but to mere mortals like Rico and I and probably the general public, it’s quite fascinating how the physician is able to select the region of interest, both with just his eyes. Is it special glasses that he wears for the computer to sense where he’s looking?

Guillaume: [00:08:08] Right. There are two types of input devices. One is an eye tracker, which is a device that is actually next to the monitor. No glasses are needed or we use a tablet, so both are devices and input devices that are used to help move those filters. The device that we’re using for the first system that we rolled out. Earlier this year is using a tablet.

Patrizia: [00:08:33] Okay.

Rico: [00:08:34] Okay. Wow, that sounds a bit almost Sci-fi. It almost feels like Star Trek or something.

Patrizia: [00:08:40] It really sounds super futuristic.

Rico: [00:08:42] Right? I mean, you know if I can wear those glasses and it follows where I want to put it. That’s the ultimate thing, right? I mean, even augmented reality, I could see you probably even advancing it further where the information will be right on the glass like that at some point.

Guillaume: [00:08:57] Eventually there, certainly eye tracker technology has, has an unlimited amount of potential and you know, currently they’re being deployed in actually laptops as a standard feature. Certainly the gaming world has helped advance the, the amount of funding in the eye tracking technology. And we’ve basically taken an off the shelf eye tracking technology, and are able to retrofit it with our device and use it as one of the input devices that we use.

Rico: [00:09:25] You know, what I like about it is that you’re dealing with an industry where the equipment is so expensive. And it’s almost legacy in some ways because even the operating

systems and some of the old systems, they might be based on windows, windows seven even as far back. And you are giving them an option to just augment existing equipment they have.

Guillaume: [00:09:47] That is a key point. And our ability to retrofit existing x-ray units is important. A cath lab, which is used for the procedure I was describing earlier, to help deploy stents. Can be $1 million or more. So if you wanted this feature to radically, dramatically reduce your risks of all these adverse events that I talked about, an administrator, a hospital may have a really tough time looking for capital to acquire another cath lab, it could cost $1 million. But if you’re able to retrofit your existing, your existing C-arm, then that is a massive benefit. So that is definitely a key feature.

Rico: [00:10:23] So the, the type of customers are you looking at are major hospitals, small local clinic? Or where’s your sweet spot as far as customers and industries?

Guillaume: [00:10:33] All of the above. So there are, there are more than 20,000 mobile C-arms in the US and those are used in hospitals for surgeries, spine trauma. They’re used by cardiologists. They’re also used by pain management facilities in outpatient facilities. They’re also used in ASCs, ambulatory surgical centers. So these mobile C-arms are deployed all over the place, in outpatient facilities and in hospitals. So anybody who is using x-ray to look inside the body without cutting it open essentially, could potentially benefit from our technology. To be clear, this is for fluoroscopic systems or C-arms. So this is not for dental equipment or plain x-ray. If I broke my arm and I go to an urgent care center where you’re taking one single exposure, the medical staff is not in the room during that exposure and the patient gets a very low amount of x-ray, a single time. This is for continuous x-ray in deployment of, let’s say stents, or let’s say in a pain management facility.

Patrizia: [00:11:48] We’re looking at physicians like urologists, cardiologists. Who else might deploy?

Guillaume: [00:11:56] Interventional radiologists, cardiologists, spine surgeons, pain management, gastroenterologists, pulmonologists that are using scopes to take biopsies inside the lung. I think you mentioned urologist, vascular surgeons. There’s, there’s seven to eight specialties that use mobile C-arms or fixed cath labs to see inside of body deploy devices.

Rico: [00:12:19] You know, I’ve found that a lot of the hospitals like Northside hospital and a lot of these major, larger facilities, companies are buying up smaller places. They’re setting up outreach satellite offices, essentially almost like a contractor based. Where they bring in the specialists into, they build a hub, provide all the machinery and then the specialists come and they rent space essentially is what they’re doing. Is that a good, I mean, how are you seeing that industry responding to what you want to do, what you’re providing?

Guillaume: [00:12:52] Yeah, that’s, that’s definitely, the consolidation in the healthcare system is certainly something that’s happening. As you get more buying power as a hospital and you

acquire competitors, let’s say I’m an ambulatories, an ASC and employee surgical center, or I have my own outpatient facility as a physician, but I’m not part of the hospital. Certainly consolidation is a trend in, in many markets. There’s pros and cons in consolidation. Us hospitals tend to have more buying power. I’m a big fan of, of competition, but at the same time, consolidation can help provide better care. So there’s, there’s pros and cons to those models. It’s not going to really impact us, our business, but certainly a trend is, is a, that’s a true trend that we’re seeing nationwide.

Rico: [00:13:42] Okay. You have two other products coming out? You mentioned that before we got on. Are they things you could talk about?

Guillaume: [00:13:49] Yeah, so the first device has been FDA cleared, and we’re currently selling today, and that’s retrofitting mobile C-arms. Mobile C-arms. Are smaller C-arms that are used by all the specialties I talked about. The next device that we will be releasing in the second half. We’re in preparation or preparing our submission is for fixed arms or cath labs. So it’s the same device. It’s just on a separate markets within the healthcare space.

Rico: [00:14:24] Okay.

Patrizia: [00:14:27] Guillaume let’s talk about Alara. It’s the FDA’s guiding principle of radiation safety. So Alara stands for?

Guillaume: [00:14:38] As low as reasonably achievable. And Alara, the objective of Alara is any amount of x-ray, is considered not good. So if you can get it as low as you can while not impacting the ability of the physician to provide the care that he or she needs to provide, then that is a, that is a good place to be. So the key, the key component of our device is that we’re able to reduce radiation without impacting image quality, negatively impacting image quality. Historically, a lot of people have struggled. At reducing the radiation exposure to the physician and medical staff. But it has come at a cost and that cost typically has been lower image quality. And when you lower image quality, you lower the opportunity of providing the best possible care you can. So Alara is that principle that the FDA and many other societies follow which is, let’s get x-ray radiation as low as we can without impacting outcome

Patrizia: [00:15:45] And let’s talk about ControlRad and how far they are able to reduce that level of radiation exposure.

Guillaume: [00:15:52] So in our FDA submission, we would do anywhere between 50 to 89% the radiation exposure to both patients and the entire medical staff inside the room. That is considered game changing.

Patrizia: [00:16:08] That is considered game changing

Guillaume: [00:16:10] Especially when you don’t negatively impact image quality.

Patrizia: [00:16:14] You talked to us earlier about some of the negative repercussions from the physicians who are continuously bombarded with this scattered radiation and you mentioned brain tumors, on which side of the head were they more likely to?

Guillaume: [00:16:26] Left sided brain tumor. So they have two times incremental risk of brain cancer compared to other medical professionals, and they have an increasing incidence in left brain. Why is left brain relevant? When the physician is at the patient they’re on the left side of the patient and it’s their left side of the brain that is closest to the x-ray tube. So there’s a direct correlation with exposure from the x-ray tube to brain tumors. So that is why the left brain tumor is a very meaningful.

Patrizia: [00:17:02] And the last time I had spoken to you at your office when it was still safe to be side by side and have an actual conversation with someone in person. You did mention there was at least one study out that indicated that your image quality. was not only not affected adversely, but improved for the physician that was testing the product. Have you had any other such tests or results from other physicians?

Guillaume: [00:17:27] That’s right. So we, we in our, in our first installations at the beginning of the year, the feedback has been, well, not only are you not negatively impacting image quality, but your image quality has actually gone up. We’ve actually improved image quality. And we thought this was going to be the case from bench testing, lab testing that we had done. But we didn’t really appreciate how clinically meaningful it was. And the feedback from this position was you have improved image quality to the point that you’re able to reduce the operating time. Cause if I can see what I need to see better and faster than I can actually reduce my operating time. If you could reduce operating time and time where you’re sedated, the cost of the OR and the advantages to the patient are very meaningful and very clinically important. So when we were out to reduce radiation and what we have found when we launched the technology is not only did we reduce radiation, but we actually clinically improved image quality. That is not part of our FDA label, in our FDA claims. But now we’re going to be, we’re going to look to further do additional testing to be able to provide that claim that and investigate if we can get that claim from the FDA. But very important outcome from these initial installs.

Patrizia: [00:18:54] Absolutely.

Rico: [00:18:57] So do you, do you have several clients that you’ve been selling to? Can you talk of any case studies right now, Guillaume, of successes that you’d like to mention?

Guillaume: [00:19:08] Yeah, so we have installations in surgical fields. We also have it in outpatient facilities. By pain management in a pain management field. And the utilization and the reductions and radiation that we’re seeing are matching what we claimed we were able to do. And we’re very pleased with that and we’re getting additional outcomes like Patrizia just

pointed out regarding image quality. So we’re very pleased with the outcomes, both in being able to deliver a very high radiation reduction and then provide better image quality.

Rico: [00:19:48] Do you have, what are you looking forward to? What developments are you, beyond the two products you’re working on, you know, long range. Do you have long range plans that you’d like to be doing in this field as well?

Guillaume: [00:20:01] Yeah. So in the next iterations we’ll be looking at further developing for other types of C-arms. So there’s a whole host of different types of C-arms and x-ray equipment. So we’ve launched it with a mobile C-arm, a GE mobile C-arm. We’re going to be doing it with a fix C-arm cath lab at the, at the risk of prying too much information is going to be on it fixed CRM with a Siemens, another vendor. And we’re in talks with all vendors and we’re getting interest from a lot of different parties and are looking to collaborate more with some of these C-arm OEMs to further expand the reach of our technology.

Rico: [00:20:42] How long have you guys been in business?

Guillaume: [00:20:46] Well, we’ve, the technology was originally launched in 2010, by three Israelis, our research development center’s in Israel. Our global headquarters are here in Peachtree Corners. And so we went through a very long period of development, which is very typical for medical devices. The ramp up in technology, in research and development of medical devices can last decades. And we are now just getting our 5, 10 K clearance, as I shared last year, and now in the midst of a commercial launch. So we’ve gone through a very long period of development and now we’re at this very exciting period in our company where we’re now launching the technology and seeing the fruits of all our labor. You know, really taking hold this year, which is really exciting. And fortunate for us, we raised our last capital round with a VC in the fourth quarter of last year. So we’re actually well capitalized and certainly wouldn’t want to be doing that fundraising now behind us in the fourth quarter. And we’re well capitalized to you know, to move the company forward and fuel the commercial launch.

Patrizia: [00:22:02] Guillaume your headquarters here in Peachtree Corners is rather new. Talk to us about why your company shifted from, was it Pennsylvania?

Guillaume: [00:22:12] Yup, Pennsylvania.

Patrizia: [00:22:13] Why Peachtree Corners, Georgia?

Guillaume: [00:22:15] So originally the, our research and developments are still in Tel Aviv and our global headquarters prior was in Radnor, Pennsylvania, which is right outside of Philly. And I was working actually for a company called Monica Technologies, which is a French medical device company based out of Paris, but the US headquarters was here actually in Atlanta as well in Duluth. And so I was already here in Atlanta. So when I joined the company as the CEO, we moved the headquarters from Radnor, Pennsylvania down here to Atlanta. I had found that,

you know, when you peel back the onion here in Atlanta, you’d be surprised at how much medical device talent you actually have here in our own backyard. Certainly it doesn’t match what you have in Boston or in San Francisco, but you’d be surprised on how many medical device talent there is here. The cost of living, it doesn’t compare to what it looks like in Philly. The weather doesn’t, you’ve got the Atlanta airports that’s, you know, for a lot of that does a lot of global travel, is very convenient. So we found Peachtree Corners in particular are very well centered, right north of Atlanta, access to 141 is very useful. 141 miles will be an interstate. I can get to the airport in 35 minutes, 40 minutes if there’s no traffic, of course. But I’m playing around traffic, so that’s okay. And you know, we have people that work here in the office that live inside their perimeter that lives North of us, that lives West of us, that lives East of us. And we find ourselves actually pretty well centralized here and certainly the cost of labor and in this building that I’m here in Scientific Park is fantastic compared to what’s even inside the perimeter, but certainly a lot cheaper than in Philly.

Rico: [00:23:59] Sure.

Patrizia: [00:24:00] Well, we’re glad you decided to settle here.

Rico: [00:24:04] And in this time of COVID-19 Philly’s not the place to be.

Patrizia: [00:24:08] Let’s talk about that a little bit. I don’t mean to be a Debbie downer, but it’s happening and it’s among us.

Guillaume: [00:24:18] Yeah.

Patrizia: [00:24:19] We stopped human activity across the globe. So how, if in any way, has COVID-19 effected ControlRad?

Guillaume: [00:24:26] Yeah, certainly COVID-19 is going to, has impacted everybody. I mean, our premise is pretty simple. We see the light at the end of the tunnel. This too will pass. And we just have to get through this period of time. Who knows what that period of time looks like. But we have to get through this time and be as productive as we can during these times. We have found that for us as a company, we’re very fortunate because we’re just launching our technology. So we had nominal cash, predict, forecasted for this year. So our burn rate in our runway is really not impacted by COVID-19. Our team in Israel and our team here in Atlanta are working very effectively remotely. We’re able to come into the office as I am today to do conduct testing on our x-ray equipment that’s here in the office. So we can, you know, very carefully and with very few people conduct what we need to conduct. Are we at 100% productivity? No. But we’re doing extremely well and find it too. And have found, frankly, in our building of habits of things that we weren’t doing prior, that we’ll probably will keep on doing. Are there meetings that I would typically have gone to that I didn’t really need to go to? Probably. Are there, you know, we’re comfortable conducting all company meetings with a team in Israel. Having a chance for team members to meet each other that probably wouldn’t had a chance to meet, probably

should’ve been doing that before. So there’s habits that we’re actually building up that we’re probably going to be building up even once we get outta here. So we have found, just stay pretty productive and are pleased with how we’re performing.

Rico: [00:26:06] It’s a, it is a tough environment. I deal with a lot of different companies and their sales staff. Just reaching out to people. There’s no landline to call anymore. You have to have someone’s cell phone essentially, or an email. So it’s a little bit more difficult to do. Are there other things that you’d like to share, Guillaume, about the company that we haven’t covered yet?

Guillaume: [00:26:32] No. I mean, listen, we’re excited to be here. I’m very thankful to be on this podcast and be part of this community. There’s a lot going on here. I’m sitting across here from Atlanta Tech Park, which is where we were before we were in this building. It’s exciting to see all the investments and energy in this place. I’m amazed at all the construction that’s going on just north of us. It certainly gave us a lot of different lunch opportunities. So it’s great to see the investment and excitement here. My kids go to Wesleyan across the street, so it’s excited to be part of this community and thanks for having me on.

Rico: [00:27:10] I appreciate that. There were several people, Robin Benfay, from Atlanta Tech Park moving Ashley Young that recommended your company, part of this profile that we did in the last issue. So they were able to speak up about you and your company.

Guillaume: [00:27:27] Great.

Rico: [00:27:28] So, and you’re right, there’s so much going on. I mean, Atlanta Tech Park with the one and a half mile Curiosity Lab track. I mean, some of the stuff is just like your technology because what’s going now there’s going to be even a bigger appeal for some of this stuff, right? We were talking a little bit before earlier about the safety of medical staff. It’s a big deal now. You know, not having the N95 mask or the protection equipment. This falls in line with that, right? We’re keeping staff safe.

Guillaume: [00:28:02] I mean, frankly, we believe the sensitivity to our technology coming out of this thing is going to be higher than it was before. Not that people didn’t care of the medical staff. And these risks that I talked about were very well documented and known. But certainly coming out of COVID-19, there’s going to be a even higher sensitivity to protecting the medical staff. So we definitely believe that that will benefit us.

Patrizia: [00:28:29] Truly innovative, truly remarkable, and absolutely touching that you’re protecting the people who are saving lives every day.

Guillaume: [00:28:36] Yes, absolutely.

Rico: [00:28:38] Well, we appreciate you coming on the show with us. For those that want to read the full article, you will find the digital edition on LivinginPeachtreeCorners.com. Go to our digital page and you’ll find that issue. The February-March issue that was held up.

Patrizia: [00:28:56] Residents may still have in their home somewhere and you can read all about ControlRod and four other very innovative companies in Peachtree Corners.

Rico: [00:29:07] Yes, yes. And we’ll be posting it to the website shortly also. So there, we’ll have the series of articles online. Guillaume, I appreciate you coming out and coming out socially safe online. It’s not zoom, but it’s close, right?

Guillaume: [00:29:23] Yeah, absolutely. All right. Thanks guys. Appreciate it.

Rico: [00:29:28] Take care. Bye.

Related

Business

SCB Construction Group Partners with CGA Reps on New Peachtree Corners HQ

Published

4 days agoon

April 15, 2025

SCB Construction Group, freshly rebranded from SteelCo, secures construction project with CGA Reps for new office HQ in Peachtree Corners

SCB Construction Group has announced a strategic partnership with CGA Reps to build a new office headquarters in Peachtree Corners. The project, encompassing approximately 26,000 square feet of innovative workspace, marks a significant milestone in advancing CGA Reps’ corporate vision while showcasing SBA Construction Group’s commitment to delivering transformative construction solutions.

In collaboration with Oakley Real Estate Partners — serving as developers of the project on behalf of CGA Reps — this venture reflects a united effort to bring cutting-edge design (from Smallwood architecture firm) and operational excellence to the commercial kitchen equipment industry.

The announcement follows several high-profile projects for SCB Construction Group in 2024, including a 72,500-square-foot manufacturing center and headquarters for Process Equipment & Controls, an impressive interior build-out for Courtesy Ford Conyers’ commercial service center and the Phase 1 completion for StoreEase Loganville — recently honored as a 2024 Smart Facility of the Year by Modern Storage Media.

A bold new chapter for CGA Reps

The new 25,890-square-foot headquarters is designed to be more than just a workplace — it is envisioned as an inspiring environment that serves both client engagements and employee creativity. CGA Reps is recognized as an industry expert in commercial kitchen equipment, representing leading manufacturers, warehousing, distributing and installing everything from fryers to commercial walk-in freezers.

The facility’s design reflects this expertise, featuring a dedicated approximately 9,000-square-foot showroom kitchen that will host equipment demonstrations, tradeshows and webinars. This dynamic space will allow CGA Reps to showcase its comprehensive product range and provide clients with hands-on experiences of the latest commercial kitchen innovations.

A standout feature of the project is its innovative approach to stormwater management. With the site comprising only three acres, sufficient space for a traditional detention pond does not exist. To overcome this challenge, the design includes an underground detention system located beneath the truck court to efficiently handle all stormwater runoff.

This solution not only maximizes the use of the available land but also reinforces CGA Reps’ commitment to sustainable practices.

“We are excited to embark on this project with CGA Reps,” said Jay Bailey, CEO of SCB Construction Group. “This partnership underscores our commitment to customer excellence in design and construction, and it is a testament to the trust our clients place in our ability to deliver projects that not only meet but exceed expectations.”

Delivering excellence through proven expertise

SCB Construction Group’s track record in 2024 has been nothing short of remarkable. Earlier in the year, the company completed a 72,500 square foot manufacturing center for Process Equipment & Controls, integrating office space within a dynamic production facility.

This project was celebrated for its innovative design that balanced operational efficiency with a modern aesthetic, utilizing IMP panels to mimic tilt-up concrete, setting new standards for manufacturing environments.

Similarly, the interior build-out for Courtesy Ford Conyers’ commercial service center demonstrated SCB Construction Group’s ability to transform conventional spaces into functional and attractive environments that cater to both customer and staff needs.

The company’s commitment to quality and precision was again evident in the successful Phase 1 completion for StoreEase Loganville. This project, which recently earned the distinction of a 2024 Smart Facility of the Year by Modern Storage Media, highlights SCB Construction Group’s forward-thinking approach to construction and design, incorporating smart technologies and design that enhance sustainability and operational efficiency.

A rebranding that reflects a vision for the future

In a move that signals its evolution and growth, SCB Construction Group has recently rebranded from its former identity, SteelCo Buildings, as it spins off its construction division. This strategic rebranding is not merely cosmetic — it represents a renewed commitment to capabilities, credibility and client-focused service.

The refreshed brand is anchored by a new tagline “Deep Expertise, High Expectations” and a clear brand promise that communicates the company’s mission: to craft exceptional construction experiences based on precision, innovation and trust.

“Our rebranding is about more than just a new name or logo; it’s a renewed promise to our clients and communities,” explained Robert Lee, marketing director at SCB Construction Group. “We believe that our updated brand identity, including our invigorated tagline and mission statement, encapsulates our dedication to pushing the boundaries of design and construction. It reflects our commitment to creating spaces that are as inspiring as they are functional.”

Transforming spaces to inspire and connect

The new headquarters for CGA Reps is expected to become a landmark facility in Peachtree Corners. Beyond its impressive architectural design and advanced construction techniques, the building is planned as a hub for innovation and collaboration.

The interior build-out will include dynamic client reception areas, interactive meeting rooms, and dedicated spaces designed to foster creativity and teamwork among employees. The layout is crafted to ensure that every area of the facility contributes to a productive and inspiring work environment.

“By investing in this state-of-the-art facility, CGA Reps is making a strong statement about the future of work,” said Bryan Young, VP of construction at SCB Construction Group. “Our team is dedicated to designing and building spaces that not only serve the immediate needs of our clients but also create environments that motivate and inspire. The new headquarters will be a testament to that vision.”

Looking ahead

The partnership between SCB Construction Group and CGA Reps marks a significant step forward for both companies. As SCB Construction Group continues to build on its legacy of excellence and innovation, this project is poised to set a new benchmark for modern office headquarters design in the region.

With a strategic focus on creating spaces that inspire, connect and drive success, the future looks promising for both SCB Construction Group and its esteemed partner, CGA Reps.

For more information on the new headquarters project or to learn more about SCB Construction Group’s portfolio, visit scbcg.com.

Related

How NetPlanner Systems powers businesses with tech-forward services and solutions

Anyone who’s been in business for more than a decade — maybe even less than that — can attest to the changes one must make to stay relevant. Such is the case with NetPlanner Systems.

During a discussion recently with Southwest Gwinnett magazine, CEO Clint Bridges explained that NetPlanner was an outgrowth of another company he started in 1983, initially in Mableton and later moved to the Peachtree Corners/Norcross area in 1985.

The first company manufactured printer and modem cables, which were in high demand during the early personal computer market boom. The company transitioned from manufacturing to providing networking services in 1987 due to the shift in the market and the desire to stay in a service-oriented business.

“Those cable assemblies sold for higher margins in the early days of the PC market. Rapidly, a lot of that manufacturing went offshore, and the margins went down, and a number of my competitors decided just to become brokers in that field,” said Bridges. “I didn’t really want to become a broker. I am very technical, very hands on, and so I sold that first business in 1986.”

Services and market reach

The contacts and trust he’d built with customers prompted him to go another route.

“Local area networking was starting to come into the marketplace, and so instead of manufacturing cable assemblies, we started to do networking, which involves putting network cabling and related hardware into commercial buildings,” he said.

NetPlanner built some of the earliest networks in the area.

“This was back in the days before there were any standards for this,” Bridges added.

Today NetPlanner provides complete design services, installation and ongoing maintenance of all communication systems in commercial buildings, focusing primarily on hardware. The company also runs a network services division that offers help desk support for small businesses without their own IT departments.

“That’s what really caused NetPlanner to be formed in 1987 — the desire to be in a service business and to provide a service that was still working with the same sorts of clientele in the computer marketplace,” he said.

NetPlanner works with a variety of commercial enterprises, as well as K-12 schools, colleges, universities and large hospital systems.

“Everything that wasn’t on the IP network in a commercial building before 1990 started to fall onto the IP network,” said Bridges. “Things that we never anticipated, including telephone systems, which were totally separate back in the 1980s, now all operate over IP-based systems.”

In addition, things like security and access control, video surveillance and similar systems all work on IP networks.

“So as time has gone on, NetPlanner has received requests from our customers to install these other systems, and we’ve embraced the other technologies that are now a part of almost all commercial buildings,” he added.

The company is now expanding its services to include nurse call services for hospitals — one of the newer markets for NetPlanner.

Security and access control systems

With ever-changing business technology needs, NetPlanner successfully keeps current with trends. With heightened security concerns everywhere, the company installs biometric readers and smart camera systems for access control.

“We provide a wide variety of smart camera systems, where they can do recognition, license plate recognition, facial recognition — all those kinds of intelligent systems for commercial spaces,” he said.

Building relationships with a wide variety of manufacturers who provide different types of software systems is how NetPlanner meets the needs of its clients.

“We work with whatever software system the particular enterprise feels is most appropriate for their needs, depending on whether they want to do license plate recognition or face recognition,” said Bridges. “We do a tremendous amount of security camera work in schools all over the southeast. And that is becoming more top of mind in school systems now.”

But there’s more. NetPlanner also provides distributed antenna systems (DAS) to improve cell phone coverage in commercial spaces.

“Cell carriers are concerned about not just signal strength, but also channel capacity — the ability to have a much larger number of users that might be around a particular cell tower at any given point in time,” said Bridges.

When installing a DAS, NetPlanner’s proficiency in coordinating with the carriers ensures compliance with carrier requirements and optimizes signal strength and coverage throughout the building.

Evolution of the technology-driven company

Anyone who knows Clint Bridges shouldn’t be surprised that he’s right in the thick of the technology boom. He started his first company at 19 and attended Southern Tech for a while before focusing on entrepreneurship.

“My passion for technology goes back to my earliest years. I’ve been fascinated by electronics and computers since I was very young. And I always had a home laboratory in the basement of the house as I was growing up,” he said. “I knew when I was in high school that I wanted to be an entrepreneur. During my time at Southern Tech, I started my first company and realized that’s what I wanted to do more than be at Southern Tech.”

NetPlanner is not only a local company. It operates fully-staffed branch offices in Augusta, Columbus and Savannah, as well as in Nashville, Tennessee; Raleigh, North Carolina; and Tampa, Florida. It has also provided services in every U.S. state, as well as parts of the Caribbean, Canada, London and Puerto Rico.

“We do projects all over the country, including some that are for companies that need to do national rollouts,” Bridges said. “A lot of our customers want to see the exact same approach used consistently throughout all their facilities across the country. So they’ll look to a company like NetPlanner to go and provide that consistent installation of all their communications technology needs in all their facilities across the country.”

Community commitment

Whether it’s working with manufacturing facilities and distributors, some of the largest big box organizations in the country, small retail businesses or anything in between, NetPlanner never loses sight of the local community.

With a home base in Peachtree Corners, the company has strong community involvement — including adopting a roadway section for clean-up efforts and participating in local chamber of commerce activities. NetPlanner has been active in several community events, such as shoe drives, food drives and charity walks, demonstrating its commitment to giving back.

“Since 2018, we’ve adopted a roadway section in the community through Gwinnett Clean and Beautiful,” said Michelle Bruck, marketing specialist at NetPlanner. “We go out about five times a year, clear debris off of that roadway and just make sure that it’s beautiful and that it’s safer for people who are walking or driving in the area.”

Nationally, NetPlanner participates in Toys for Tots and Walk to End Alzheimer’s.

“Not only [do we give back] in our headquarters location, but all of our branch offices look for ways to help, get involved and support our communities that we’re part of,” Bruck added.

NetPlanner’s marketing efforts include social media, direct marketing and trade shows, with support from Vox-Pop-Uli for branded materials and printed media.

“When we first started using Vox-Pop-Uli, we had just a straightforward vendor relationship, but they very quickly became a partner to us,” said Bridges. “Vox-Pop-Uli has actually set up a company store on our behalf where our employees can purchase branded material, branded clothing, ball caps and those sorts of things. And they also handle printed media — things that we would use at trade shows.”

Looking forward

With technology moving at a warp speed, NetPlanner relies on a lot of repeat business.

“Bandwidth requirements are increasing year after year,” Bridges said. “Fiber optic cabling that we might have installed 10 years ago won’t support the data rates that are needed today, so it needs to be changed out in many cases.”

Many of the customers that he’s been with for several decades use NetPlanner’s services over and over.

“We’ve gone into the same building and re-cabled it over and over again as the different category levels of copper cabling have advanced,” he said. “The demands on fiber are now way beyond what they were even five years ago because the capacity has increased so much.”

And as everyone is embracing artificial intelligence, Bridges said he’s working to keep up.

“Everyone is well aware of what’s happening in the artificial intelligence space. And what’s really amazing to us is the number of new data centers that are being built across the United States by all the major players,” he said. “It’s kind of hard to imagine even being able to keep up with all that. We do a lot of data center work ourselves, and are trying to engage with more of our customers to help build some of these newer data centers.”

He added that the artificial intelligence boom is causing so much additional strain on the network infrastructure across the country, there are concerns about how it’s all going to be powered.

“I think everyone’s concerned,” he said. “Everyone that’s involved in this is wondering how we’re going to meet the bandwidth demands, the capacity demands, the power demands to make all this work.”

Staying ahead of the curve

With decades of experience, Bridges offers advice for all types of businesses starting out — put technology needs into your business model early on.

“The companies that struggle the most with technology are the ones that wait until after everything with the building is developed and completely built before they realize that they need Wi-Fi or some other network installation done,” he said. “It’s just a much more efficient process if we’re involved as early as possible to help design the network, along with the building structure itself.”

He also emphasized the importance of staying ahead of technological advancements to avoid falling behind.

“As fast as technology moves, if you get behind the power curve, it’s really hard to catch up,” he added.

The Local Thread: This business profile series is proudly supported by Vox-Pop-Uli, championing local stories and the communities we serve.

Related

Peachtree Corners resident, Bill Frey, founder of Illuminating Design Inc., has stepped into the limelight on the acclaimed reality series The Blox to vie for the coveted title of the greatest start-up company in the nation.

The program follows Frey and his fellow contestants as they tackle a series of high-stakes business challenges, offering viewers an unprecedented look at the trials, triumphs and transformation of an emerging entrepreneur.

Now in its sixteenth season, The Blox bills itself as “the largest live-in entrepreneurship competition in the galaxy.” Over the years, it has evolved into a trending docuseries, available for viewing on multiple platforms — the free mobile app (for Android and iOS), on Prime Video, at betablox.com or on Facebook at BetaBlox.

Joining The Blox

Twenty years ago, Frey saw an opportunity to bring exceptional service, quality design and accountability to a rising lighting industry. Guided by his entrepreneurial spirit, he has sought opportunities to take his business to new heights and found just that in The Blox.

Unlike conventional entrepreneurial competitions, The Blox, a brainchild of MTV reality star and entrepreneur Weston “Wes” Bergmann — best known for his appearances on shows like The Real World and The Challenge — offers a new, groundbreaking format. Participants are immersed in a unique environment, living together and confronting a series of challenges that test their entrepreneurial acumen.

Frey’s talent and vision propelled him to be among the fortunate few selected to compete on show out of an impressive pool of 50,000 applicants.

“I am humbled and honored to be a part of The Blox, a game-changing platform that has given me the opportunity to evolve both personally and professionally,” he shared. “The show has been an incredible learning experience, and I am grateful for the chance to showcase my business and its potential on such a remarkable stage.”

You can follow Frey as he is featured competing in different entrepreneurial challenges throughout the series, which is divided into an eight-episode arc that premiered on March 23. New episodes are released weekly.

For more information about Bill Frey and Illuminating Design, visit illuminating-design.com.

Related

Read the Digital Edition

Subscribe

Keep Up With Peachtree Corners News

Join our mailing list to receive the latest news and updates from our team.

You have Successfully Subscribed!

From Food Creations to Handmade Jewelry: Wesleyan Kids Prep for Artist Market 2025 [Podcast]

Peachtree Corners Roundabout Plans, Tech Park Housing and Zoning Updates [Podcast]

Innovation, Security and Connectivity

Registration Now Open for Light Up the Corners 2025

Peachtree Corners Prepares for Another Roundabout

Experience Shakespeare in the Park with Contemporary Classics’ Twelfth Night

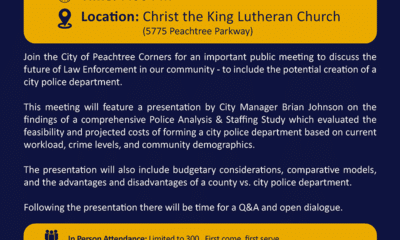

The Future of Law Enforcement in Peachtree Corners: Community Meeting

SCB Construction Group Partners with CGA Reps on New Peachtree Corners HQ

SCB Construction Group Partners with CGA Reps on New Peachtree Corners HQ

The Future of Law Enforcement in Peachtree Corners: Community Meeting

Peachtree Corners Prepares for Another Roundabout

Experience Shakespeare in the Park with Contemporary Classics’ Twelfth Night

Registration Now Open for Light Up the Corners 2025

From Food Creations to Handmade Jewelry: Wesleyan Kids Prep for Artist Market 2025 [Podcast]

Peachtree Corners Roundabout Plans, Tech Park Housing and Zoning Updates [Podcast]

Innovation, Security and Connectivity

Light up the Corners [Video]

Capitalist Sage: Business Leadership in Your Community [Podcast]

Cliff Bramble: A Culinary Adventure through Italy

Top 10 Brunch Places in Gwinnett County

A Hunger for Hospitality

THE CORNERS EPISODE 3 – BLAXICAN PART 1

Top 10 Indoor Things To Do This Winter

The ED Hour: What it takes to Remove Barriers from Education