Business

ControlRad, Developing Innovative Solutions that Dramatically Reduce the Lifetime Risk of Radiation Exposure

Published

5 years agoon

Vibrant Technology at the Heart of Five Innovative Companies, one of five companies profiled

Founded in 2010 by three men of Israeli descent, ControlRad has recently relocated from Pennsylvania to Georgia. I was able to speak to CEO Guillaume Bailliard as he settled in at their new Global Headquarters in Peachtree Corners.

They moved from Atlanta Tech Park to their new office space at 275 Scientific Dr. N.W. after securing $15 million from Questa Capital in September. “That helped fuel the growth of the company, including planting our flag here, at this facility,” Bailliard said.

Their Research and Development Team, comprised of 20 R&D engineers, is located in Kfar Saba, just outside of Tel Aviv. “The number one place in the world today for startups per capita in Israel,” Bailliard shared.

X-rays Come at a Cost

To fully appreciate ControlRad’s innovation, it’s important to understand a bit of x-ray technology. Hint: think ‘control radiation.’

“The radiation you get from x-ray is ionizing radiation—high-energy wavelengths or particles that penetrate tissue to reveal the body’s internal organs and structures. Ionizing radiation can damage DNA.” [Radiation Risk from Medical Imaging (2018), Harvard Health Publishing, Harvard Medical School]

X-rays allow us to see inside the body without invasive surgery. Traditionally, static x-ray is used if you break your arm, in order to see the fracture. It’s the same type of x-ray you get at the dentist’s office. “There is very little risk with that single exposure,” Bailliard explained.

However, continuous x-ray or Fluoroscopy, used by doctors like cardiologists, spine surgeons and urologists to see specific organs in real-time and to deploy devices inside the body like stents, without having to perform exploratory surgery, “subjects medical staff and patients to a tremendous amount of dangerous and unnecessary x-ray exposures in a single procedure,” Bailliard said. “A certain percentage of that prolonged radiation exposure scatters outside the body to the medical staff and to patients needlessly.”

During a fluoroscopic procedure, the physician is at the table beside to you, deploying the devices and getting radiated in very close proximity to the x-ray unit.

What Drives ControlRad’s Innovation?

The issue is that much of the scattered radiation reaches the medical staff. “They get roughly 150,000 worth of chest x-rays over a lifetime. This is a lot like the NFL concussion story,” Bailliard said, “in the sense that the issues with concussions have always been there, but it is only recently that we truly understand the long-term impact of repeated concussions.”

Similarly, medical staff has always been subjected to radiation, but the adverse effects of this have not been well-documented until now. Risks include increased incidents of cataracts, atherosclerosis, strokes and left-brain tumors. (The x-ray tube is closest to the left side of the physician’s head during procedures.)

Don’t be Afraid to Seek Treatment

While we may have a fluoroscopic procedure once or twice in a lifetime, physicians are performing them repeatedly throughout the day. ControlRad helps protect the medical staff providing life-saving treatment to patients.

“I don’t want readers to be afraid of going to see a cardiologist to get treated, or to get an x-ray of the hand,” Bailliard said. “Everyone should ask the right questions about the risks of radiation with their physicians. The risks for patients are very low. It’s a risk-benefit ratio and the benefits typically greatly outweigh the risks.”

How Low Can You Go?

Since no amount of radiation from an x-ray is good for you, ControlRad adheres to the FDA espoused guiding principle of radiation safety: ALARA, which stands for: As Low as Reasonably Achievable. In other words, how low can you get radiation exposure without impacting the ability to treat patients?

Am I the only one singing “How Low Can You Go” in my head right now?

To that end, it is ControlRad’s mission to dramatically reduce the unnecessary risks associated with gratuitous radiation exposure without compromising image quality or workflow. It’s an undertaking that benefits both patients and physicians, but their primary focus is on protecting medical staff who are in harm’s way for the span of their careers.

ControlRad Reduces Radiation by up to 89%

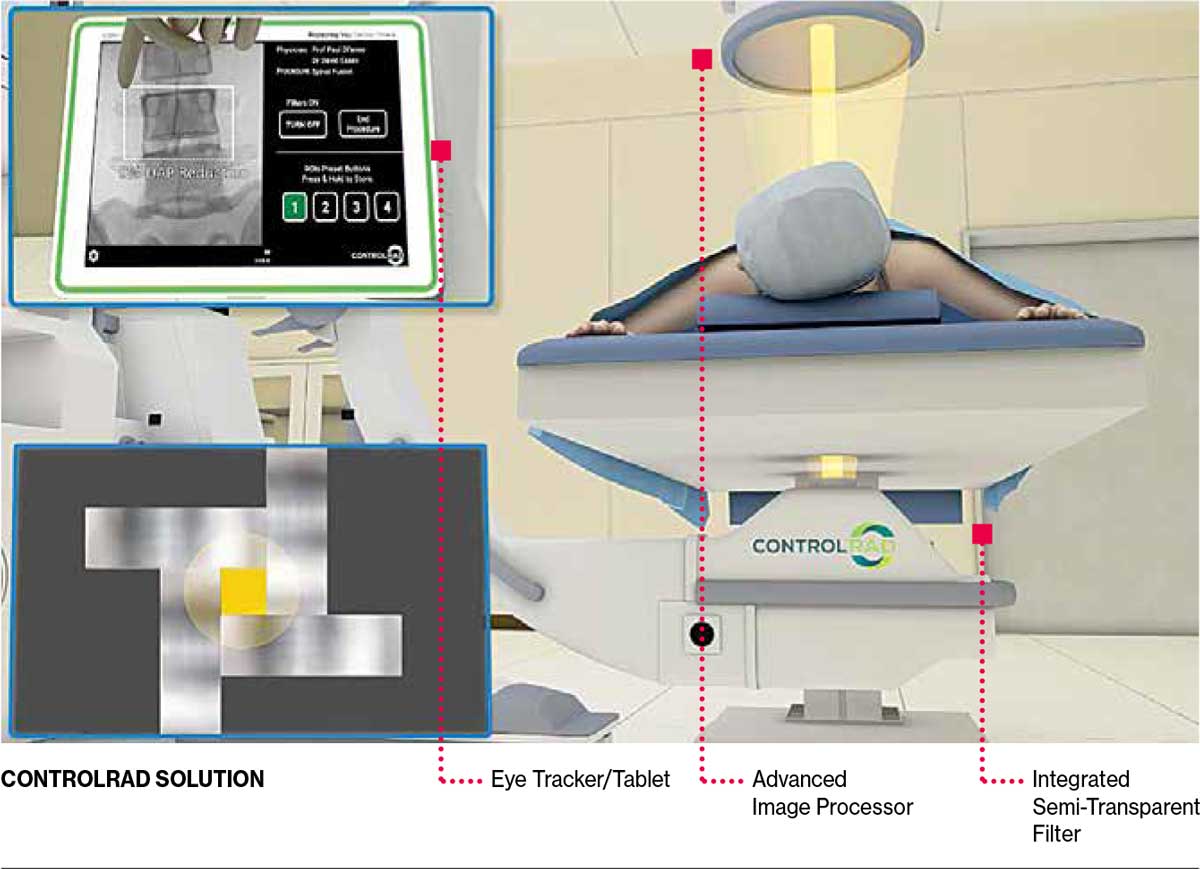

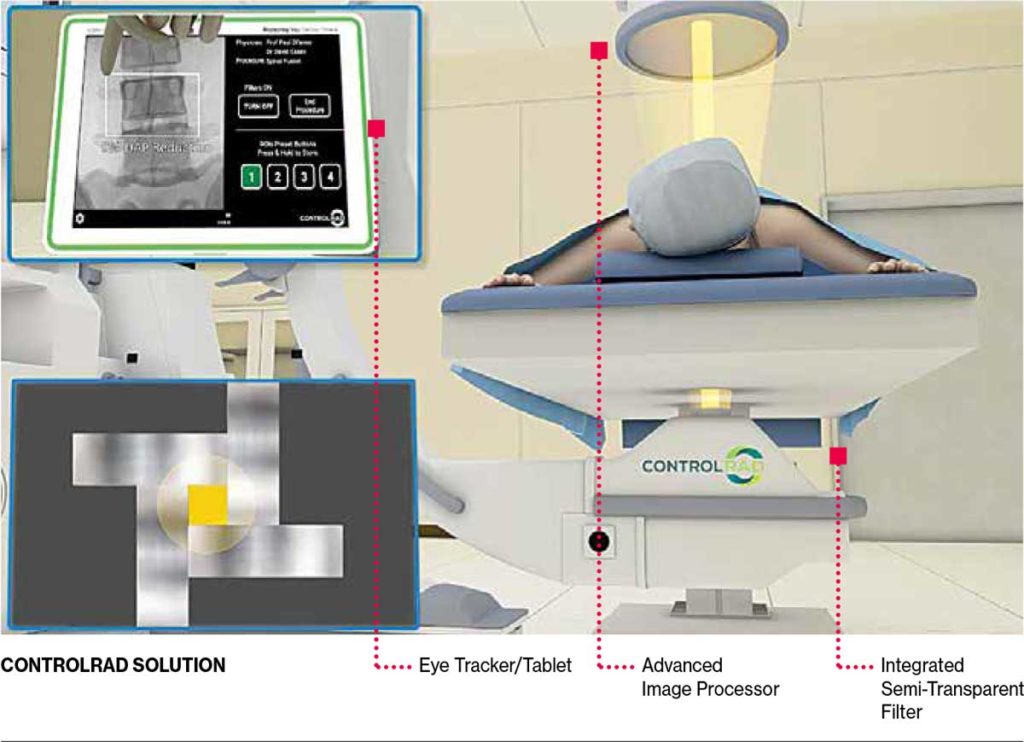

510(k) Cleared—the FDA has granted permission to go to market—ControlRad’s device consists of three components retrofitted onto existing x-ray units. (See Figure 1.)

- EYE TRACKER / TABLET

Used to select the region-of-interest (ROI), either by detecting where the doctor is looking, or by allowing the doctor to draw an ROI manually on the tablet. - INTEGRATED SEMI-TRANSPARENT TITANIUM FILTER

The filter sits on top of the x-ray tube. It moves in real-time focusing on the selected ROI and reducing the x-ray beam outside the ROI, thereby filtering out unnecessary scatter radiation. - ADVANCED IMAGE PROCESSOR

Image processing algorithms help improve the image quality delivered to the physician.

The Launch

A published and peer-reviewed study has demonstrated a 75% radiation reduction to both patient and medical staff, using ControlRad’s technology. This ground-breaking device has recently been launched and is currently in limited release.

“The objective is to pressure test the product, the feature sets, our logistics, our service, and our training,” Bailliard said. “We’ve done a number of installations and are actually looking into having some installations in Atlanta. We’re in the process of talking with those teams.”

Feedback

Dr. Andrew Cappuccino in Niagara Falls suggested that not only was the radiation exposure to himself and to his patient drastically reduced, but he believes he saw an improvement in image quality as well.

“It makes sense to us that there is an improvement in image quality because we’re reducing the amount of scatter radiation in the ROI, but we’ll do additional studies to validate that,” Bailliard noted. “Our objective was to reduce unnecessary x-ray radiation and not negatively impact image quality. What we’re finding is that there’s potentially a very strong improvement in image quality as well.”

Why Peachtree Corners?

Bailliard cited the convenient location, its proximity to Atlanta, as well as access to a critical mass of medical device talent. “The key to any business is to be able to attract the right people. Being nicely centralized in this area we have folks coming from Marietta, from down-town and from further north.”

He also referred to the fact that the cost of doing business in Peachtree Corners is lower than in the Northeast where they were previously located and certainly lower than in Atlanta.

Perhaps my favorite reason they’ve chosen our city for their global headquarters: “We’re outside of the craziness of inside the perimeter, yet we’re in this Technology Park. That’s been the key,” Bailliard stated.

Looking to the Future

I wondered aloud if one day, patients would be able to seek out physicians who employ ControlRad’s technology.

“Actually, hospitals that are looking at our technology are looking to market to patients. Because there is a benefit to patients, we’re reducing the amount of unnecessary radiation exposure. That’s a good story,” Bailliard proclaimed.

Related

Patrizia hails from Toronto, Canada where she earned an Honors B.A. in French and Italian studies at York University, and a B.Ed. at the University of Toronto. This trilingual former French teacher has called Georgia home since 1998. She and her family have enjoyed living, working and playing in Peachtree Corners since 2013.

Business

Peachtree Corners Grows Business Opportunities Through Economic Development

Published

1 week agoon

May 6, 2025

Most residents and business owners in Peachtree Corners probably think they know all about the economic development and strategic planning of Peachtree Corners, but do they really?

Peachtree Corners Business Association invited Peachtree Corners Economic Development Director Betrand Lapoire and Partnership Gwinnett Director of Economic Development Andrew Hickey to its After Hours Speaker Series on March 27 to discuss the city’s growth from a 1971 master plan to a bustling city with 42,000 inhabitants and 40,000 jobs.

Key points included the importance of business retention and expansion, with 24 projects last year creating 1,600 retained jobs, 1,600 new jobs and $250 million in new capital investment.

The Curiosity Lab, a world-class innovation center, was emphasized as a significant attraction. The city’s zoning and infrastructure plans were also discussed, focusing on balancing office and residential development to maintain a vibrant, sustainable community.

Matching jobs to residents

Although Peachtree Corners is just a teenager in terms of being an incorporated city, the foundation for this vibrant, fast-paced economic hub was laid more than 50 years ago by technology pioneer Paul Duke.

“Peachtree Corners was the first master-planned, business innovation technology park in metro Atlanta,” said Lapoire. “It was in response to the brain drain of technology with Georgia Tech graduates leaving the area.”

While the city may have a small-town feel, it’s the largest in Gwinnett County by population, but not land mass, he added.

“The city started from a commercial, industrial, R&D base and then was expanded around it,” said Lapoire.

Though home to more than 42,000 residents, most of the jobs in Peachtree Corners are filled by people who live outside the city, he added.

“So we have this interesting mismatch, in a way, although not unusual,” said LaPoire. That creates traffic and transit issues. So that means that one of the solutions is to create more jobs here to fit the profile of the community.”

He presented charts that show professional services, consulting and engineering as the largest job categories. The next tier of businesses are wholesale and manufacturing.

“So we have a good mix of industry,” he said.

A five-year plan

The city has a five-year economic development plan (2023-2028) that outlines strategies for attracting and retaining businesses, with education and workforce development being key components.

Partnership Gwinnett has similar goals as Peachtree Corners, but on a larger scale.

“We are the county’s sales and marketing arm for all 17 cities now, and we receive funding from both municipal sources as well as existing businesses here — both in Gwinnett and outside of Gwinnett as well,” said Hickey.

He shared how Partnership Gwinnett is designed to drive a lot of major corporations toward doing business inside and with Gwinnett County.

“One of the biggest things that we talk about that I’m sure it seems like most of us here, if you live here, you work here, you understand it. It’s the diversity that exists here in Gwinnett,” he said. “With a diversity index of 85, that means if we walk out of the Hilton here and we say hello to somebody, there’s an 85% chance they’re from a different ethnic or cultural background than ourselves, which to you and I may seem normal because that’s the life that we live in.”

He added that for companies, there’s a tremendous value in that, whether they have stated values, or they’re just making hiring decisions to get a wide range of candidates to fill those roles. Additionally, because of the proximity to Atlanta, Gwinnett County has a great labor draw.

Partnership Gwinnett

Partnership Gwinnett plays a significant role in recruiting businesses, expanding existing companies and developing the workforce. Hickey showed how the organization was involved with more than 24 projects last year.

“A majority of those were expansions, and that is a common thread you’ll see in economic development,” he said. “In business retention, expansion is so vital to working with our existing companies to make sure that they have the resources they need.”

He added that’s what leads to new investment and job creation in the community.

The organization also focuses on redevelopment projects, working with cities and the county to improve infrastructure and community amenities — especially strong educational institutions such Georgia Gwinnett College, Philadelphia College of Osteopathic Medicine and others.

Quality of life

In closing, both men stressed the importance of recruiting companies and developing the workforce, along with one aspect that means a lot but may not be as obvious — quality of life.

“It’s definitely evident that people like to work where they live — the whole live, work play experience,” said Hickey. “I joke that the part that people really have the most questions about, and are most excited to learn about, is new events at The Forum or Gwinnett Place Mall.”

Although they want to know what’s the next major company coming to Gwinnett, people REALLY want to know about how to spend their leisure time.

“That speaks to the importance of ensuring that we have a great community,” he said. “So at Partnership Gwinnett we work with all of our cities, and the county government as well, [on] a kind of a best-practices trip.”

He added that the peer tour allows everyone to know what the neighboring communities are doing and share the good news.

“We will take all of these elected officials, but also city staff, to different cities across the Southeast,” he said. “Last year, I believe they went to Huntsville, and have been to Greenville, Chattanooga — all cities that have done some really cool redevelopments that have taken their city to the next level. Our goal is to learn from them.”

Related

Business

Two Peachtree Corners Business Leaders Named Finalists for EY Entrepreneur Award

Published

3 weeks agoon

April 23, 2025

Ernst & Young’s Entrepreneur Of The Year celebrates ambitious entrepreneurs who are shaping the future

Ernst & Young LLP (EY US) recently announced the finalists for the prestigious Entrepreneur Of The Year 2025 Southeast Award, and two local, Peachtree Corners business leaders — David Quirk, president and CEO of DLB Associates Consulting Engineers PC and Erin Hanson, founder and CEO of Guardian Sports — made the list.

Hanson’s Guardian Sports is a family-owned company dedicated to serving athletes through safety and performance improvements in sports equipment. Major products include the Guardian Cap, PEARL ball and Guardian Infill serving the sports industry.

DLB Associates is a U.S.-based consulting engineering firm specializing in mission-critical and complex built environments. With more than 40 years of expertise, DLB delivers innovative, technology-driven solutions in engineering, commissioning and operations worldwide.

Celebrating entrepreneurial leaders

Now in its 40th year, Entrepreneur Of The Year recognizes the bold leaders who disrupt markets through the world’s most ground-breaking companies, revolutionizing industries and making a profound impact on communities. The program honors those entrepreneurs whose innovations shape the future and pave the way for a thriving economy and a hopeful tomorrow.

The Southeast program celebrates entrepreneurs from Alabama, Georgia, North Carolina, South Carolina and Tennessee.

An independent panel of judges selected 36 finalists for their entrepreneurial spirit, purpose, growth and lasting impact in building long-term value.

“This year’s finalists are leading examples of innovation, perseverance and resilience, illuminating paths to a brighter future for their industries and communities,” said Chevy Arnold, Entrepreneur Of The Year Southeast Program co-director.

“Their commitment to excellence transforms challenges into opportunities, inspiring us all,” added Kimberly Kicklighter, Entrepreneur Of The Year Southeast Program co-director.

Entrepreneur Of The Year honors many different types of business leaders for their ingenuity, courage and entrepreneurial spirit.

The program showcases original founders who bootstrapped their business from inception or who raised outside capital to grow their company; transformational CEOs who infused innovation into an existing organization to catapult its trajectory; and multigenerational family business leaders who reimagined a legacy business model to strengthen it for the future.

Including Quirk and Hanson, the 2025 Southeast finalists are:

- Marc Hodulich | 29029 | Atlanta, Georgia

- Damon Stafford | Alpine Intel | Charlotte, North Carolina

- Lou Hensley | Aspida | Durham, North Carolina

- Matthew Dent | Buffalo Rock Company | Birmingham, Alabama

- Melanie Little | Colonial Pipeline Company | Alpharetta, Georgia

- Will Bartholomew | D1 Training | Franklin, Tennessee

- Rene Diaz | Diaz Foods | Atlanta, Georgia

- David Quirk | DLB Associates Consulting Engineers PC | Peachtree Corners, Georgia

- Markus Scott | EyeQ Monitoring | Atlanta, Georgia

- Jon Gosier | FilmHedge | Atlanta, Georgia

- John Fitzpatrick | Force Marketing | Atlanta, Georgia

- Dr. Barry Patel | Galt Companies | Atlanta, Georgia

- Dr. Wade Smith | Galt Companies | Atlanta, Georgia

- Charles Gillespie | Gambling.com Group | Charlotte, North Carolina

- Kevin McCrystle | Gambling.com Group | Charlotte, North Carolina

- Mike Griffin | Griffin Brothers Companies | Cornelius, North Carolina

- Erin Hanson | Guardian Sports | Peachtree Corners, Georgia

- Dan Beem | Hissho Sushi | Charlotte, North Carolina

- Aaron Siegel | Home Team BBQ | Charleston, South Carolina

- Marc Murphy | Ignite Digital Services | Charleston, South Carolina

- Miller Chalk | Inglett & Stubbs, LLC | Mableton, Georgia

- Liza Rodewald | Instant Teams | Southern Pines, North Carolina

- Stephen Andresen | McClancy Foods & Flavors | Fort Mill, South Carolina

- Travis LeFever | Mission Mobile Medical Group | Greensboro, North Carolina

- Cyrus Mojdehi | Northway Homes | Charlotte, North Carolina

- Connor Ryan | NutraSky | Alpharetta, Georgia

- Fritz Owens | OTR Solutions | Roswell, Georgia

- Christopher Chuang | Relay, Inc. | Raleigh, North Carolina

- Kurt Jacobus | restor3d, Inc. | Durham, North Carolina

- Tom Kendrot | Shearwater Health | Nashville, Tennessee

- Teak Shore | Southern Lighting Source | Cumberland, Georgia

- Cindy Eckert | Sprout Pharmaceuticals | Raleigh, North Carolina

- Bryan Moore | TalkShopLive Inc. | Nashville, Tennessee

- Tina Moore | TalkShopLive Inc. | Nashville, Tennessee

- Igor Marinelli | Tractian | Atlanta, Georgia

- Joan Butters | Xsolis | Franklin, Tennessee

You can learn more about the finalists at ey.com/en_us/entrepreneur-of-the-year-us/southeast/winners-finalists.

Regional award winners will be announced on June 25 during a special celebration. The winners will then be considered by the national independent panel of judges for the Entrepreneur Of The Year National Awards, which will be presented in November at the annual Strategic Growth Forum®, one of the nation’s most prestigious gatherings of high-growth, market-leading companies.

About Entrepreneur Of The Year

Founded in 1986, Entrepreneur Of The Year has celebrated more than 11,000 ambitious visionaries who are leading successful, dynamic businesses in the U.S., and it has since expanded to nearly 60 countries globally.

The U.S. program consists of 17 regional programs whose panels of independent judges select the regional award winners every June. Those winners compete for national recognition at the Strategic Growth Forum® in November where national finalists and award winners are announced.

The overall national winner represents the U.S. at the EY World Entrepreneur Of The Year™ competition.

For more about the award, visit ey.com/us/eoy.

Related

Business

SCB Construction Group Partners with CGA Reps on New Peachtree Corners HQ

Published

4 weeks agoon

April 15, 2025

SCB Construction Group, freshly rebranded from SteelCo, secures construction project with CGA Reps for new office HQ in Peachtree Corners

SCB Construction Group has announced a strategic partnership with CGA Reps to build a new office headquarters in Peachtree Corners. The project, encompassing approximately 26,000 square feet of innovative workspace, marks a significant milestone in advancing CGA Reps’ corporate vision while showcasing SBA Construction Group’s commitment to delivering transformative construction solutions.

In collaboration with Oakley Real Estate Partners — serving as developers of the project on behalf of CGA Reps — this venture reflects a united effort to bring cutting-edge design (from Smallwood architecture firm) and operational excellence to the commercial kitchen equipment industry.

The announcement follows several high-profile projects for SCB Construction Group in 2024, including a 72,500-square-foot manufacturing center and headquarters for Process Equipment & Controls, an impressive interior build-out for Courtesy Ford Conyers’ commercial service center and the Phase 1 completion for StoreEase Loganville — recently honored as a 2024 Smart Facility of the Year by Modern Storage Media.

A bold new chapter for CGA Reps

The new 25,890-square-foot headquarters is designed to be more than just a workplace — it is envisioned as an inspiring environment that serves both client engagements and employee creativity. CGA Reps is recognized as an industry expert in commercial kitchen equipment, representing leading manufacturers, warehousing, distributing and installing everything from fryers to commercial walk-in freezers.

The facility’s design reflects this expertise, featuring a dedicated approximately 9,000-square-foot showroom kitchen that will host equipment demonstrations, tradeshows and webinars. This dynamic space will allow CGA Reps to showcase its comprehensive product range and provide clients with hands-on experiences of the latest commercial kitchen innovations.

A standout feature of the project is its innovative approach to stormwater management. With the site comprising only three acres, sufficient space for a traditional detention pond does not exist. To overcome this challenge, the design includes an underground detention system located beneath the truck court to efficiently handle all stormwater runoff.

This solution not only maximizes the use of the available land but also reinforces CGA Reps’ commitment to sustainable practices.

“We are excited to embark on this project with CGA Reps,” said Jay Bailey, CEO of SCB Construction Group. “This partnership underscores our commitment to customer excellence in design and construction, and it is a testament to the trust our clients place in our ability to deliver projects that not only meet but exceed expectations.”

Delivering excellence through proven expertise

SCB Construction Group’s track record in 2024 has been nothing short of remarkable. Earlier in the year, the company completed a 72,500 square foot manufacturing center for Process Equipment & Controls, integrating office space within a dynamic production facility.

This project was celebrated for its innovative design that balanced operational efficiency with a modern aesthetic, utilizing IMP panels to mimic tilt-up concrete, setting new standards for manufacturing environments.

Similarly, the interior build-out for Courtesy Ford Conyers’ commercial service center demonstrated SCB Construction Group’s ability to transform conventional spaces into functional and attractive environments that cater to both customer and staff needs.

The company’s commitment to quality and precision was again evident in the successful Phase 1 completion for StoreEase Loganville. This project, which recently earned the distinction of a 2024 Smart Facility of the Year by Modern Storage Media, highlights SCB Construction Group’s forward-thinking approach to construction and design, incorporating smart technologies and design that enhance sustainability and operational efficiency.

A rebranding that reflects a vision for the future

In a move that signals its evolution and growth, SCB Construction Group has recently rebranded from its former identity, SteelCo Buildings, as it spins off its construction division. This strategic rebranding is not merely cosmetic — it represents a renewed commitment to capabilities, credibility and client-focused service.

The refreshed brand is anchored by a new tagline “Deep Expertise, High Expectations” and a clear brand promise that communicates the company’s mission: to craft exceptional construction experiences based on precision, innovation and trust.

“Our rebranding is about more than just a new name or logo; it’s a renewed promise to our clients and communities,” explained Robert Lee, marketing director at SCB Construction Group. “We believe that our updated brand identity, including our invigorated tagline and mission statement, encapsulates our dedication to pushing the boundaries of design and construction. It reflects our commitment to creating spaces that are as inspiring as they are functional.”

Transforming spaces to inspire and connect

The new headquarters for CGA Reps is expected to become a landmark facility in Peachtree Corners. Beyond its impressive architectural design and advanced construction techniques, the building is planned as a hub for innovation and collaboration.

The interior build-out will include dynamic client reception areas, interactive meeting rooms, and dedicated spaces designed to foster creativity and teamwork among employees. The layout is crafted to ensure that every area of the facility contributes to a productive and inspiring work environment.

“By investing in this state-of-the-art facility, CGA Reps is making a strong statement about the future of work,” said Bryan Young, VP of construction at SCB Construction Group. “Our team is dedicated to designing and building spaces that not only serve the immediate needs of our clients but also create environments that motivate and inspire. The new headquarters will be a testament to that vision.”

Looking ahead

The partnership between SCB Construction Group and CGA Reps marks a significant step forward for both companies. As SCB Construction Group continues to build on its legacy of excellence and innovation, this project is poised to set a new benchmark for modern office headquarters design in the region.

With a strategic focus on creating spaces that inspire, connect and drive success, the future looks promising for both SCB Construction Group and its esteemed partner, CGA Reps.

For more information on the new headquarters project or to learn more about SCB Construction Group’s portfolio, visit scbcg.com.

Related

Read the Digital Edition

Subscribe

Keep Up With Peachtree Corners News

Join our mailing list to receive the latest news and updates from our team.

You have Successfully Subscribed!

Digital Edition

Official City Merchandise Line Debuts This Saturday at Town Green

Paul Duke STEM High School Student Earns CGO Scholarship

World Blood Donor Day Starts Here: Theo’s Miracle, Katherine’s Mission [Podcast]

Executive Function: A Tribute to Working Moms

Peachtree Corners Grows Business Opportunities Through Economic Development

Simpson Elementary Marks Exceptional Children’s Week

Peachtree Corners Hosts Discussion About the Future of Local Policing

Atlanta’s Dog Howl-O-Ween Festival Moving to Peachtree Corners for 2025

D1 Training Brings New Fitness Concept to Peachtree Corners

Peachtree Corners Hosts Discussion About the Future of Local Policing

City of Peachtree Corners Awarded Certificate of Achievement From GFOA for Seventh Straight Year

Simpson Elementary Marks Exceptional Children’s Week

Executive Function: A Tribute to Working Moms

Official City Merchandise Line Debuts This Saturday at Town Green

Peachtree Corners Grows Business Opportunities Through Economic Development

Light up the Corners [Video]

Capitalist Sage: Business Leadership in Your Community [Podcast]

Cliff Bramble: A Culinary Adventure through Italy

Top 10 Brunch Places in Gwinnett County

A Hunger for Hospitality

THE CORNERS EPISODE 3 – BLAXICAN PART 1

Top 10 Indoor Things To Do This Winter

The ED Hour: What it takes to Remove Barriers from Education